Can China produce "Top Quality?" I would like to go into a product range we first started work on 8yrs ago....a range that has sold ever since..... I believe it is a good insight towards designing/manufacturing new product.

Firstly Insight: I had been asked by a Lighting Distributor of Quality to design an exterior range of products from start to finish. The range needed to be formed using Stainless Steel 316 and Copper that would "age".

Having been involved in Lighting for 10yrs prior and selling a lot of Garden Lighting of the same "ilk" I knew some quarms of the installers to consider.

The client did not want "Cheap" he wanted "High Quality" and this to represent a signature range for his company.

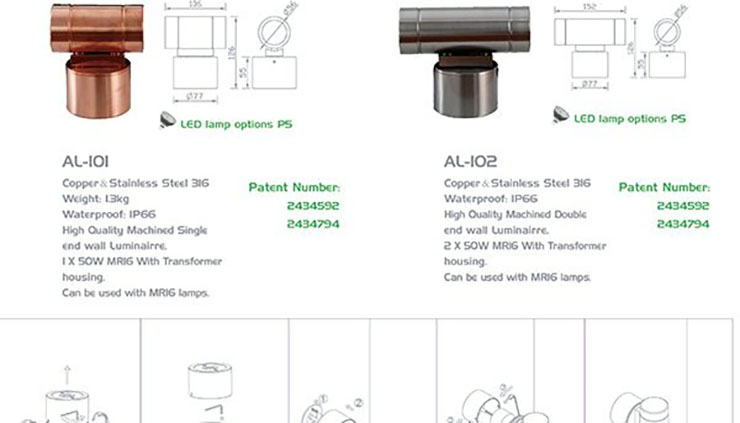

To That end the first thing in design we did not wish to have was "Screw Threads" that would deteriorate over time. So we pushed ahead with "Push over O+rings" to seal the fittings.

The next was for the "base" as I had been aware for some time having allen key studs located close to the wall was a pain for installers as they could only turn said key half circle (As the key hits the wall). Also when a base plate is fixed and if the head not straight it is hard to re-fix..result "lights on strange angles". So I kept the fixing nuts close to the top of the plate, the base screwing down as one piece.

You can then adjust to straight and lock the Allen Keys to fix...Hey presto!

We did not wish to have "unsightly" spacing between Base and head so we intigrated a "spacer" also formed from SS and Copper into the design.

The Most difficult and challenging part of any of the designs was the "adjustable arm" as we wanted to get 350Degree head rotation and direction without the base nor head loosing IP rating integrity.

The LH Cables required to go through this so the engineering had to be ultra precise to acheive this whilst not showing any cables at all.

For this we created two parts of the arm, locked together over o+ring via a allen key. The rotation aspect was solved by having a "Spring Loaded" bottom section that turned in a groove. However this was?very very hard to acheive and perfect, but with a lot of hard work we managed it..

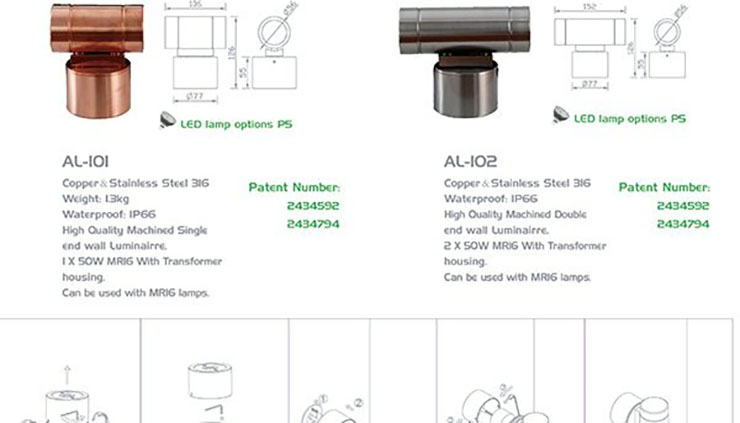

The Range needed "options" so "Shallow base" and "cowell" were designed also, allowing these to be swapped for main parts. (Seen above).

The Drawings our Engineer was drawing were sent many times, much consultation and changes pre-tooling. The whole process lasted 3-4 months but it was a great challenge for all of our team to get this right.

Once designs were completed the very complex challenge of production/moulding needed to be carefully planned out.

At first when taking on the "challenge" I had visited a few Garden Lighting Factories but generally the passing of information would be difficult indeed, So I instead looked for the correct parts fabricators.

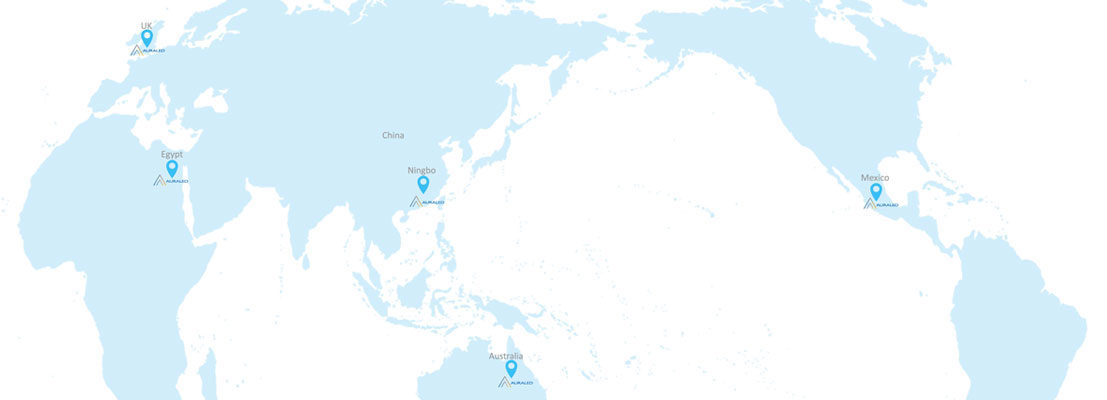

To that end I found a "loss wax" moulding factory very skilled in exterior SS316 and Copper Lighting parts, signed agreements and decided to run in our production at our Ningbo site.

The tooling period was difficult but our engineers followed the "proccess" carefully and we assembled our first samples some 8months after the initial discussions.

These samples were sent to the "client" who we must note shared the tooling fee+s with us, these being very expensive. On arrival the client was thrilled, but still cautiously tested them to ensure the quality of material and against leakage.

A month Later we started our first production order of the whole series. All were tested, packed carefully, our designer creating amazing instruction sheets for the client and shipped in a container to the client.

Proof of how good they were was around 2 weeks after landing when I recieved an e-mail from a trading company in Guangzhou titled "do you make"?? with pictures of a man holding our fittings in his hand inside a lighting retailer. ?I read down the thread below the trading companies e-mail it said "dear xxxxx, We just had these new samples arrive from a local supplier, they are excellent quality can you please source".

We were stunned as to how this trading company had our information and then it dawned on us that staff had inadvertantly placed our product codes on all the internal lables, the same product codes on the design patents we had filed.

Obviously the "trading companies" enquiry was re-buffed with, these products are patent pending and "if you want to copy, get client to send you sample and invest on tooling and getting them right".

I spoke then to our Client who knew exactly who had sent pictures "Oh that will be this Lighting retailer we sent samples for display to, he buys in some small items from China".

So the range sold from then on, Patents being granted and a steady supply for the last 7years.

However a few things did come out of this that created a better understanding for me of China. The first being the comment from a "Local Chinese garden lighting producer" who viewed these and told me "we would never manufacture such high quality as we need cheap for price".

The second being "Speed of world connection" as as soon as no sooner had our first order started distribution requests were being pinged to gain prices.

Thirdly: If you wish to Distribute Lighting do not look at what you can just buy from China and re-sell. This Client did not and from careful attention to detail working with the right people he has developed excellent range and maintained name for Quality.

For us it is just another example of a section of Lighting we can aid distributors in....

So if you are fortunate to ever see one of these products...at 4mm thick SS316, Electro Polished, with even the Allen key nuts being tooled in 316...then you will know the answer to the Question...

Can China produce Quality...Yes is the answer if you have the right "working together" relationship and the "producer" knows what Quality means.

Barrie@auraledlighting.com

0086 13566002389

Cover image: