Truth about Cheap LED panels..Testing..Changes. (May 28th, 2015)

(2019/9/17)

Clients in a number of Nations often ask me to explain the difference of our LED panels so that they can also explain onto the installers, project managers and potential clients.

I wrote only last week about how it was "floodlights and now it is LED Panels" after I went to meet some clients at the HK spring lighting fair and witnessed a number of price slashing items.

I did state in said post that I would update people with the results of testing that I am undertaking on every product that was shown at the fair. Now I am just taking apart one version with Phillips Driver and 4014 diodes, see results at the end of this thread.

Sounds strange to test everyone elses product but when I put my name (Barrie Vesty) to a product I do not just say "Oh its better" I use fact and testing to tell people why.

See living in China for nearly 10years I have seen every type of product available and my experience/knowledge comes from a Quality Lighting background. People relied upon that in the past so I do not see why this should change now, tomorrow or next week.

So I am going to list a number of points on that in this post and try to disect "Fact from fiction" as I have done in a series of YouTube Videos.

The reason for this disection is recently I had seen a "share" from a trading company that had been commented upon. The Share just said "we make Quality LED Panels"..nothing about SDCM, UGR, Material grades, Thermals, construction and many points that go towards a excellent LED panel.

Before I do speak about construction can I just state how dissapointed I am that a number, not one, not two, not three but a number of so called Lighting Distributors purely buy the cheapest possible product. Some clients have said to me "the market price is x" and I say "I am not selling it if it is not fit for purpose".

So Disection and difference...Firstly explanation...of the Light...

I start with the Light itself: An LED edge lit Panel relies upon the LEDs being placed at the side emitting light into an Acyrlic sheet, the Light bounces off a printed surface and travels through the "diffuser" that splits said light again to create a "even look".

What Materials you use in that determine the Quality. Use your imagination to think of Light travelling into something from the side and being reflected downward, it would figure the greater thickness you have on this area the more chance of forward relection.

Therefor we use 4mm Thick Acrylic Light guide Plate not 3mm or 2.5 as used on many cheap versions.

Note Acrylic has a habit of discolouring especially around the areas the Light is being fired through it. So we must use imported material Acrylic From Japan as the clarity/Quality of this material is very important. Many Claim this usage but do not.

Second is the Quality of the front diffuser as this splits the bounced light and is the last layer in the smoothness. Many cheap versions are using PP and not PC material, the latter on ours is 750degree glow wire tested.

Third and very important on LED side lit Panel lighting is the quality of the print on the LGP (Light Guide Plate) or Acrylic as mentioned before. For this we use a ultra fine laser printing as the Dot matrix is ultra small high uniformity, remember the light comes from the side and bounces forwards from this so the uniformity dictates the smoothness of the panel.

The Fourth layer is a reflective sheet and this is important when combined to the above.

The Fourth layer is a reflective sheet and this is important when combined to the above.

The Fifth essentail ingredient to this is the diodes themselves. Many use 2835 Diodes but they are spaced so close together that:

a) heat becomes an additional concearne.

b) The Beam angles intersect quicker therefor loosing efficiency from Diode Lumen to Front output lumen.

The 4014 Diode as I have just tested is ultra Narrow so then only works with thinner grade materials.

From our detailed analysis the best diode for this is the 5630 diode as the spacing allows us to maximise the LM/Diode to Lumen output. We will use Samsung or Epistar LM80 for this.

The reason these Five?are so important is they effect the SDCM, UGR and the surface area look of a Panel.

Second explanation: Good construction....considering Thermals.

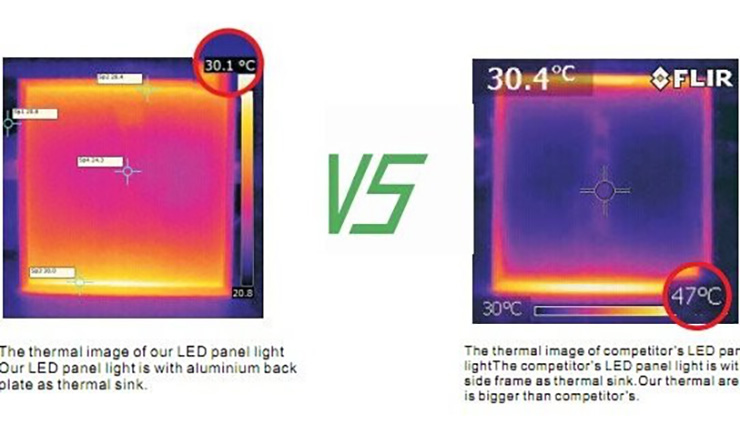

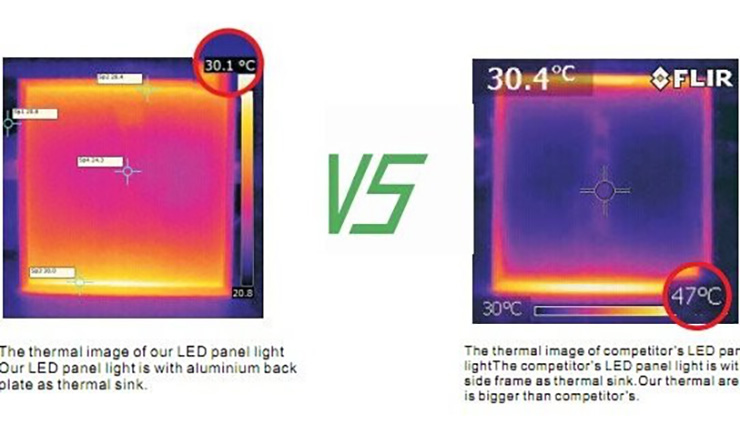

Our LED Panels are Thermally much better than all of the cheap versions as I will go onto explain (See image), as we know thermals are very important factors of LED lighting as the L70 (Lumen depreciation to 70%) will be quicker with more heat.

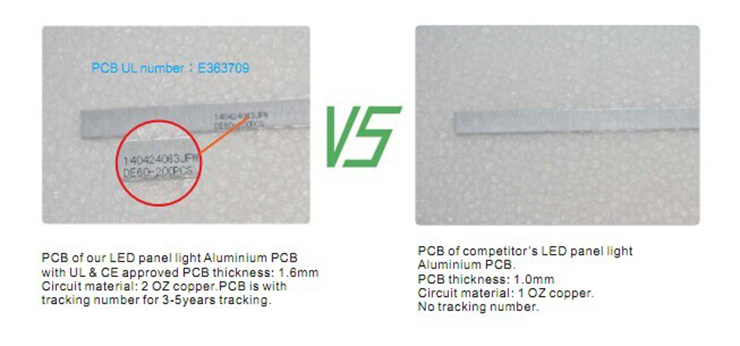

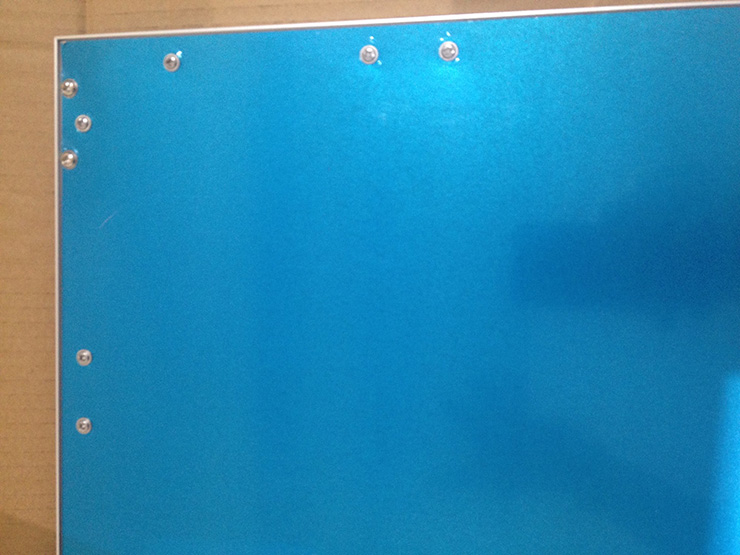

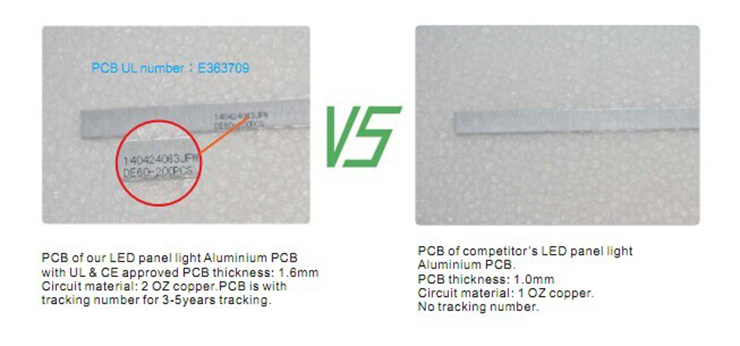

The first step is how our PCBs sit into our panel. We form a Aviation grade Aluminium tray (Like a Baking tray) 1mm thick, The 1.4mm UL approved PCBs sit inside the Lip of this tray so the whole tray becomes a heat sink.

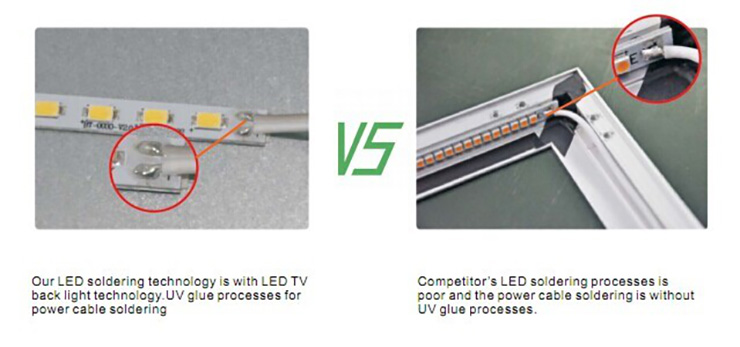

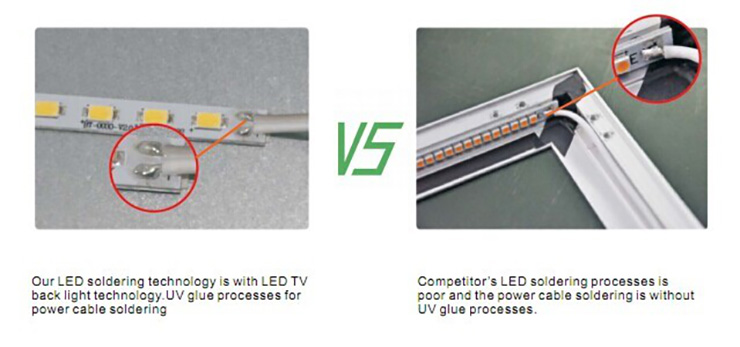

Second is the "soldering" as we Solder internal connections then coat using an ultrasound technique formed in LED screen construction to cover and protect all Solder points to ensure they have no chance to "short".

Coming Back to PCB usage, the 1.4mm Aluminium PCBs are UL approved so have higher copper content, less resistance and can transfer the heat better to our Aluminium Baking tray style back.

Then the Aluminium tray goes into an Aluminium frame, said frame surrounds the tray and has all the fixings integrated into the frame design. So if you want suspended you lock in easily the suspension cables, Surface lock in simple brackets, Flush lock in flush mountings ad recessed simply lock on our Spring stands.

Then the Aluminium tray goes into an Aluminium frame, said frame surrounds the tray and has all the fixings integrated into the frame design. So if you want suspended you lock in easily the suspension cables, Surface lock in simple brackets, Flush lock in flush mountings ad recessed simply lock on our Spring stands.

Therefor not only is the Panel better radiated but the fixings are easier to position (I will go onto explain).

Above "Demo Kit" can be purchased for $80 to show your clients the layers of a excellent Panel Light.

Now to ?Panels just tested and the reason for the "Mutton Dressed as Lamb" Headline....

WOW..Samsung Diode...Phillips Driver only $30....for a 40W Panel as the leaflet rammed down every foreigners face at the recent HK Light fair.

You will ALL be getting offers on cheaper LED panel lights recently.

Samples have just arrived of Cheap versions...Here is the test:

Firstly I will commend Phillips for supply on the Driver, I can understand from a commercial sense to become involved in Supply of controlls as it adds credibility to the final product.

But I do have slight issue with the driver supplied and this is only a suggestion not a insult on the quality as I am not going to discuss in the thread any testing on this.

My Point refers to the "Loop in loop out nature" of AC input side and is only a suggestion to them of a possible improvement.

The AC input only offers two pole Live/Neutral and only offers clamp down for one cable. So the Electrician still needs to run a ring main circuit and earth provision.

No one on this front has considered Earth continuity and making a provision to ease the install time by having full loop in loop out provision on a driver (food for thought). CHANGE; I JUST HAVE!!!

Update: Heard of issues on said driver with High failure rates, would like verification.

However from the rest of the sample this is the "Lamb" portion.

Now to the panel itself:

Firstly removing the what seems endless screws down on the ultra thin sheet steel backing does not take long at all.

Why mention sheet steel backing? Well at 0.3mm thick and screwed straight down to the ultra thin aluminium frame means that this has a small impact upon heat transfer.

Taking this off I reveal a lot of reflective tape covering the LGP (light Guide Plate) and PCBs. It is what I find below that interests me.

The Acrylic (LGP) is China Made 3mm Thick and will discolour after about 12months of usage turning yellow around the edges.

The printing is not as uniform as ours by far and seems more screen printed.

Now for the LEDs/PCBs A visual inspection of the diodes on the PCBs shows many diodes not straight and therefor the soldering will have weaker points contained within. A PCB is mapped for diodes to sit onto prior to going to reflow wave solder but these diodes must be straight as then the contacts are good.

A good manufacturer will like us have a QC at that point to straighten any diodes to ensure good contact.

The wires connecting the PCBs have open solder points without cover protection. While the danger of shorting to the frame is low this should be considered.

For fixing in the Grid type ceiling this Panel is fine...use for other fixings and you have to take parts off and add parts.

I Will post again with the total figures, UGR, LM, CRi, R9 etc......on the outputs etc.....But?regardless of this the Thermal image above shows that having Full Aluminium backing removes a lot more heat...So therefor the Lifespan will be longer...coupled to the right materials...!!

So At the moment I feel it is really "Mutton Dressed as lamb"......

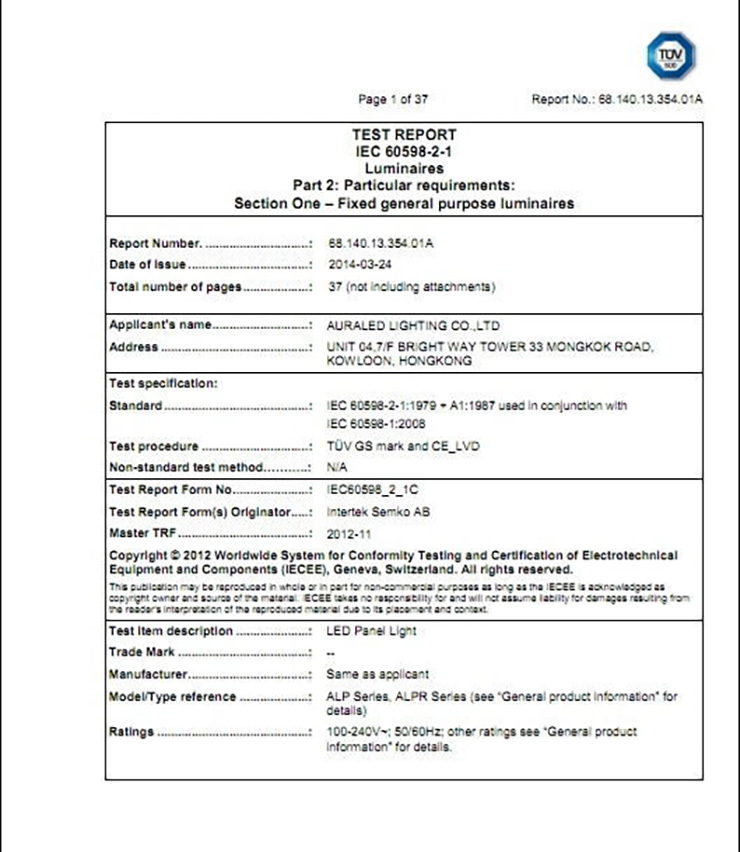

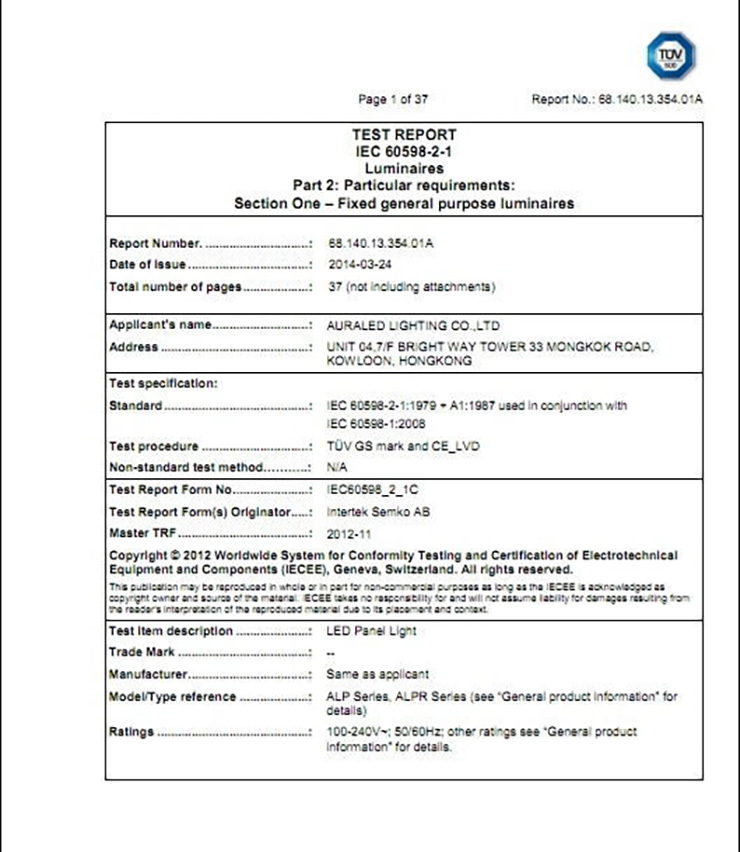

It is why When the project uses our products they know they will last and the quality will be better....regardless of adding brand names to components. Our approvals are FULL approvals not just on the EMC;

Just a few images of our projects below.

Barrie@auraled.co.uk

Barrie@auraledlighting.com

13566002389

UK Stocks: 0044 203 4189870

Auraled UK Ltd

Products built to Quality standards not to the latest price points......

Then the Aluminium tray goes into an Aluminium frame, said frame surrounds the tray and has all the fixings integrated into the frame design. So if you want suspended you lock in easily the suspension cables, Surface lock in simple brackets, Flush lock in flush mountings ad recessed simply lock on our Spring stands.

Then the Aluminium tray goes into an Aluminium frame, said frame surrounds the tray and has all the fixings integrated into the frame design. So if you want suspended you lock in easily the suspension cables, Surface lock in simple brackets, Flush lock in flush mountings ad recessed simply lock on our Spring stands.